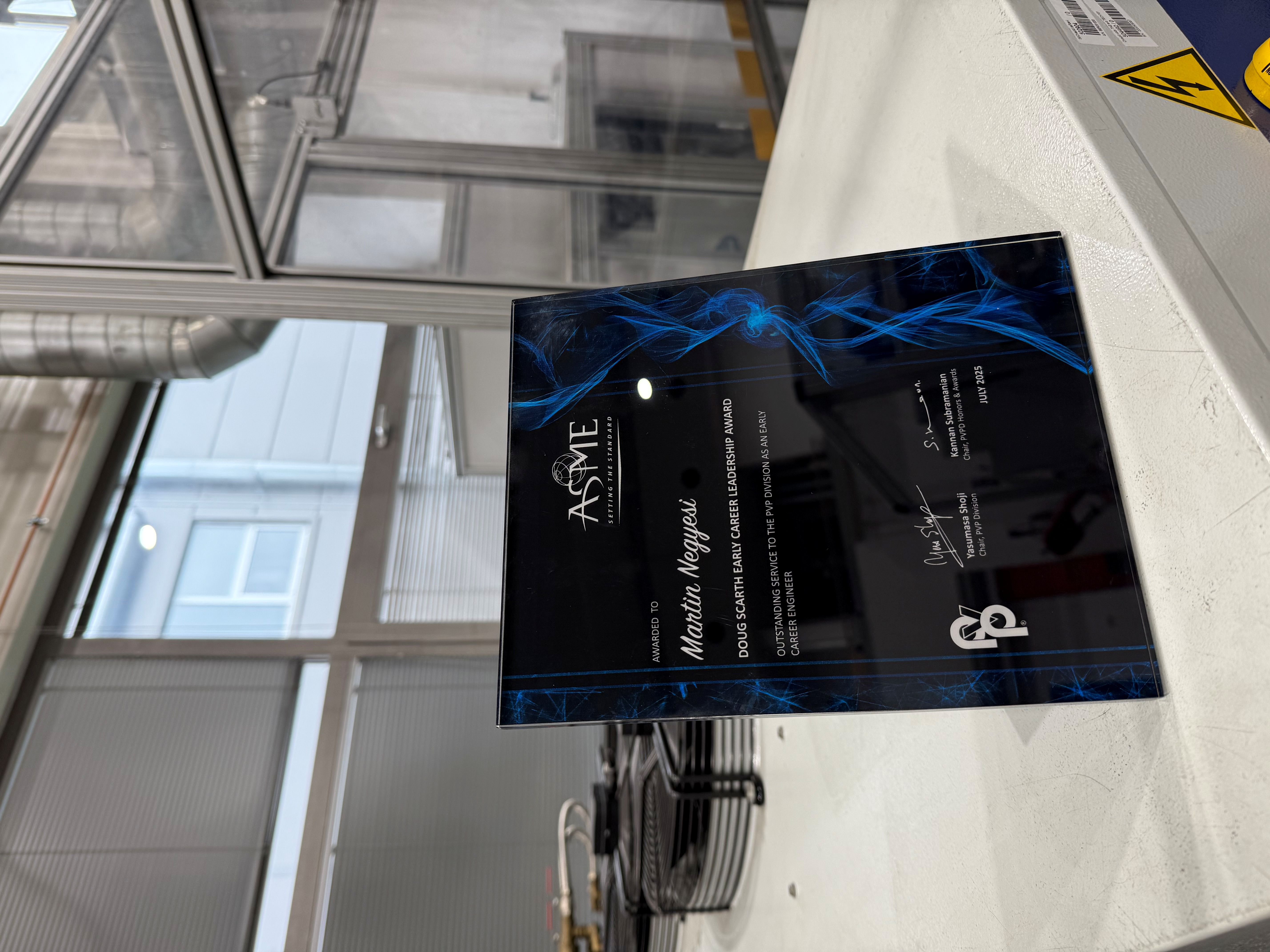

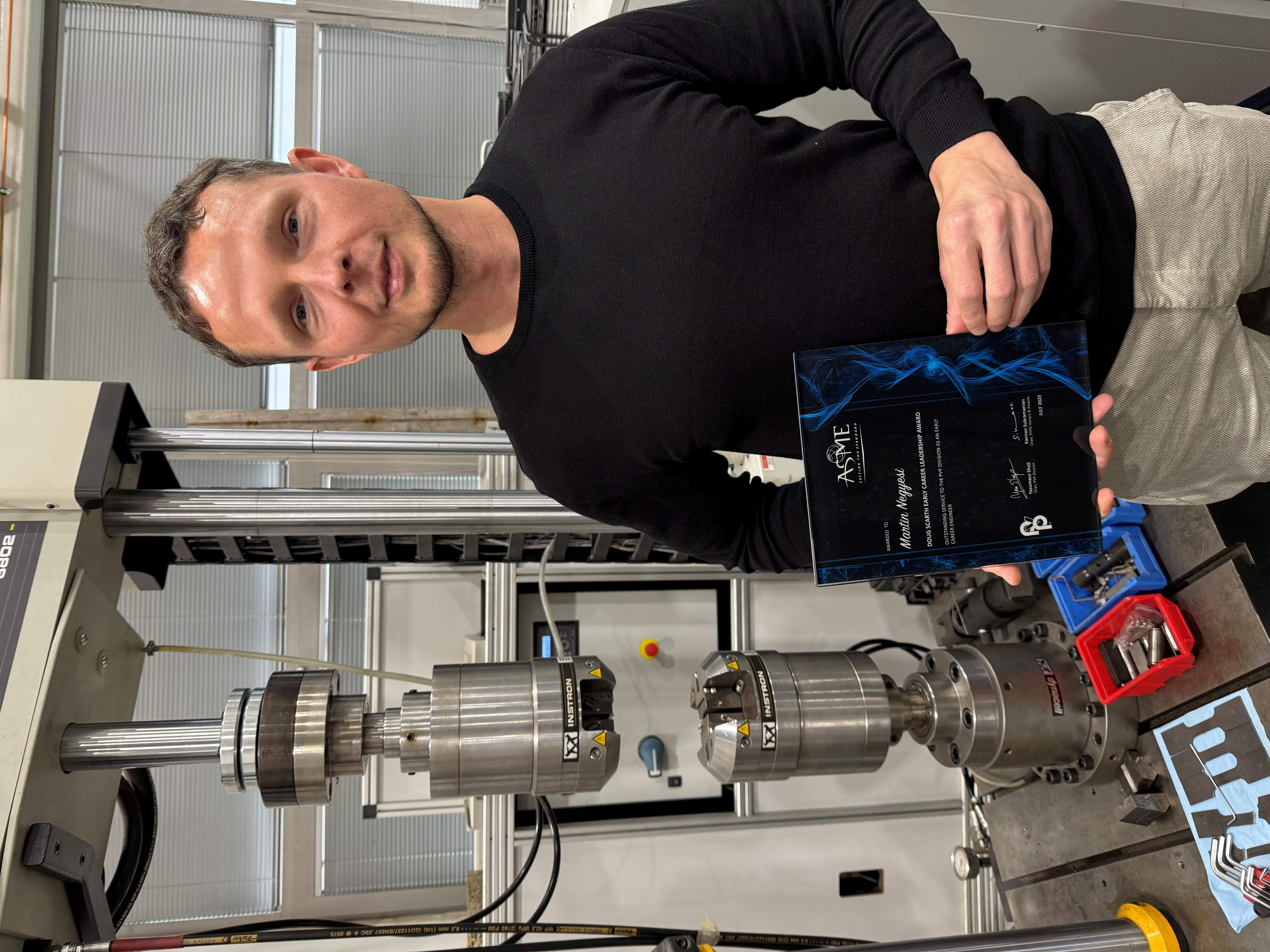

Ing. Martin Négyesi, Ph.D., a researcher at the Centre for Advanced Innovation Technologies (CPIT) of the Faculty of Materials Science and Technology (FMT) at VSB – Technical University of Ostrava, has received the prestigious Doug Scarth Early Career Leadership Award, presented annually by the American Society of Mechanical Engineers (ASME) to one early-career scientist. The award was presented at this year’s Pressure Vessels and Piping (PVP 2025) Conference as recognition for his outstanding contributions in the area of pipeline flaw evaluation, especially through his involvement in the Pipe Flaw Evaluation (PFE) and Flaw Evaluation Reference Curves (FERC) working groups.

Martin Négyesi is also a co-author of proposed revisions to ASME technical manuals, specifically the section serving as a guide for power plant operators focused on evaluating the stability of components with detected flaws. He also contributed to the development of a less conservative approach to calculating fatigue crack growth rates in austenitic steels – an approach based on a thorough analysis of real-world data, which is expected to be incorporated into the new edition of the manual in 2027.

What does this award mean to him, and why is research in materials science worth pursuing? We asked him in a short interview.

What are you currently working on within ASME, and what do you consider your greatest contribution?

Right now, I’m involved in revising a section of the ASME Boiler and Pressure Vessel Code, which provides guidance for nuclear power plant operators and other industrial facilities when flaws are found in piping or pressure vessels. For instance, we’ve proposed a new calculation method for fatigue crack growth in austenitic stainless steels. This method is less conservative, yet it’s based on an in-depth analysis of real data. It has been accepted and should become part of the manual’s new edition in 2027.

We’re also working on integrating the method of instrumented indentation into the ASME manual – a non-destructive way to measure the mechanical properties of materials, especially in cases where traditional tensile testing isn’t feasible.

What is, in your view, the value of international collaboration?

ASME is a globally recognized nonprofit organization that brings together top experts from across the world – from Westinghouse, Rolls-Royce, Framatome, and Japan’s JAEA, to name a few. For smaller countries like the Czech Republic, participating in such structures is incredibly valuable. On our own, we couldn’t achieve the same results compared to much larger and better-funded nations. Collaboration allows us to contribute meaningfully despite limited resources and to gain access to cutting-edge knowledge and expertise.

What does the Doug Scarth Early Career Leadership Award mean to you personally?

It’s a huge honor. Doug Scarth is a long-standing figure in ASME, active in several working groups within the PVP division, and we know each other personally. I see this award as a strong affirmation that what I do is meaningful and has quality. And, of course, it’s a great motivation to continue my work and collaboration with this respected international organization.

From International Cooperation to Real-World Applications in Energy

Martin Négyesi began collaborating with ASME thanks to Prof. Strnadel, head of the CPIT, who connected him with Dr. Hasegawa, a long-standing member of the PFE and FERC working groups. Today, Martin is a fully integrated member of these expert teams, contributing to the revision of technical manuals used around the world.

At the same time, he maintains a strong connection with practical research. At CPIT VSB-TUO, he focuses on developing non-destructive testing methods, particularly instrumented indentation, which has wide applications in industry. This year, his team acquired new testing equipment as part of the REFRESH project, allowing for material testing at elevated temperatures – crucial for understanding how materials perform under extreme conditions, such as those in power plants.

Previously, Négyesi and his colleagues published a paper on creep damage in heat-resistant steels used in energy facilities. Now, he is planning new tests to determine creep rates of these materials. His work thus has both international impact and direct relevance to what’s happening in Czech laboratories and companies.

We congratulate Martin Négyesi on receiving this significant international award and thank him for his excellent representation of FMT and VSB-TUO on the global stage.